A Richmond high-tech startup spun out of the Triumf particle accelerator is making its technology smaller to make the company bigger.

CRM GeoTomography Technologies Inc. developed technology that detects subatomic particle – muons -- that bombard the Earth from space to essentially X-ray what’s below the ground to produce 3D geological maps for mining and exploration companies.

Recently, the company rebranded as Ideon Technologies Inc. and brought on a new CEO, Gary Agnew, to take the company from R&D to commercialization.

Two of the original founders are still with the company. Based in Richmond, the company employs nine people.

“We see the opportunity to really solve some very big, high-value problems for industry,” said Agnew.

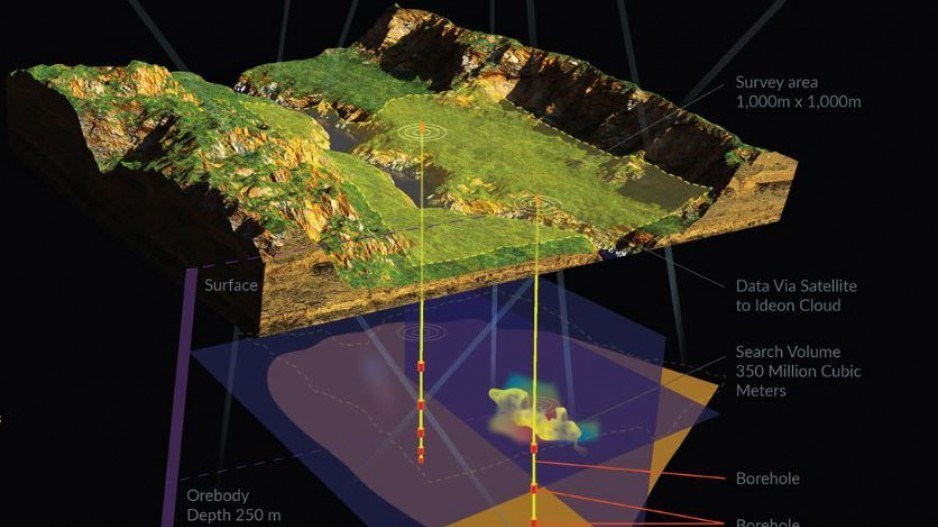

The technology Ideon developed uses muon detectors, placed underground, to produce 3D maps of ore densities. It can’t distinguish what types of metals are below ground, but it can determine just how dense the ore bodies are.

That could eliminate the need for a whole lot of conventional test drilling. Typically, a mining or exploration-development company would need to drill hundreds of test holes to determine where mineral deposits are and how dense they are.

Only a couple of drill holes are needed to place the Ideon sensors.

“That compares to – if you were just drilling that area – to be 100 or 150 drill holes over time,” Agnew said. “We’re making a massive reduction in drilling activity, the cost, the environmental impact. We’re publishing a 10-X reduction in drilling activity.”

The Ideon sensors are placed underground, up to one kilometre. The original version of the technology was the size of a kitchen table, which meant that it could only be placed in existing mine shafts.

A number of big mining companies, including Vancouver’s Teck Resources (TSX:TECK.B), has tested the technology.

“A number of these trials have been blind trials,” Agnew said.

In other words, before getting Ideon to run their surveys, the companies already knew, from conventional drilling, what the ore densities were in the trial area.

The technology has been demonstrated to work. The challenge now is to shrink the detectors, from about the size of a kitchen table to a toaster so that it can fit down industry standard bore holes.

“The technology’s proven already,” Agnew said. “The work we’re doing is miniaturization. It’s an engineering challenge – it’s not a technology proving challenge.

“By the end of this year we will have the bore hole detector developed and will go into further trials with key mining companies over the first quarter and early into the second quarter next year.”

Ideon’s business model is as a service industry, not a manufacturer. The companies that have already tested the technology didn’t get the surveys done for free – they paid to have them done.

“Up until now, it’s been bootstrapped,” Agnew said. “All of our trials have actually been paid trials.”

While the company is already technically at the commercial stage, it doesn’t expect to be fully commercial until next year.

“We’re working on the detector that fits down industry-standard bore holes, and that really is what is going to open the market up very significantly, once we’re able to fit into the industry’s current processes and exploration methodology.”